Leave Your Message

In the pursuit of enhanced performance and efficiency in various systems, optimizing the air chamber has emerged as a critical factor for engineers and designers. Recent industry reports suggest that systems with well-optimized air chambers can improve energy efficiency by up to 30%, leading to significant cost savings and reduced environmental impact.

The air chamber plays a vital role in regulating pressure, reducing noise levels, and enhancing overall system functionality. Moreover, according to a study conducted by the International Energy Agency (IEA), improving the design of air chambers can lead to a remarkable increase in airflow and thermal regulation, which is essential for applications ranging from HVAC systems to pneumatic tools. With such substantial impacts, understanding how to effectively optimize your air chamber is crucial for achieving maximum performance and efficiency in any operational context.

The air chamber plays a vital role in regulating pressure, reducing noise levels, and enhancing overall system functionality. Moreover, according to a study conducted by the International Energy Agency (IEA), improving the design of air chambers can lead to a remarkable increase in airflow and thermal regulation, which is essential for applications ranging from HVAC systems to pneumatic tools. With such substantial impacts, understanding how to effectively optimize your air chamber is crucial for achieving maximum performance and efficiency in any operational context.

Optimizing an air chamber involves a keen understanding of key performance metrics that drive efficiency and effectiveness. One crucial metric is the chamber's pressure drop, which can significantly affect the airflow and system performance. According to the ASHRAE (American Society of Heating, Refrigerating, and Air-Conditioning Engineers), even a minor pressure drop of just 1-inch water gauge can result in a 10% reduction in system efficiency. Monitoring and managing this pressure drop not only improves performance but also contributes to energy savings.

Another important factor is the humidity level within the air chamber, which can influence thermal comfort and air quality. The EPA (Environmental Protection Agency) suggests that maintaining relative humidity between 30% to 50% can improve occupant comfort and reduce mold growth. Regularly measuring humidity levels using hygrometers can help identify areas for improvement and optimize the chamber’s conditions. Implementing these metrics is vital for ensuring maximum operational efficiency and performance in air chamber systems, creating a healthier indoor environment while lowering energy costs.

This chart illustrates the key performance metrics for optimizing air chamber efficiency, focusing on dynamic pressure, temperature, and air flow rate across different operational scenarios.

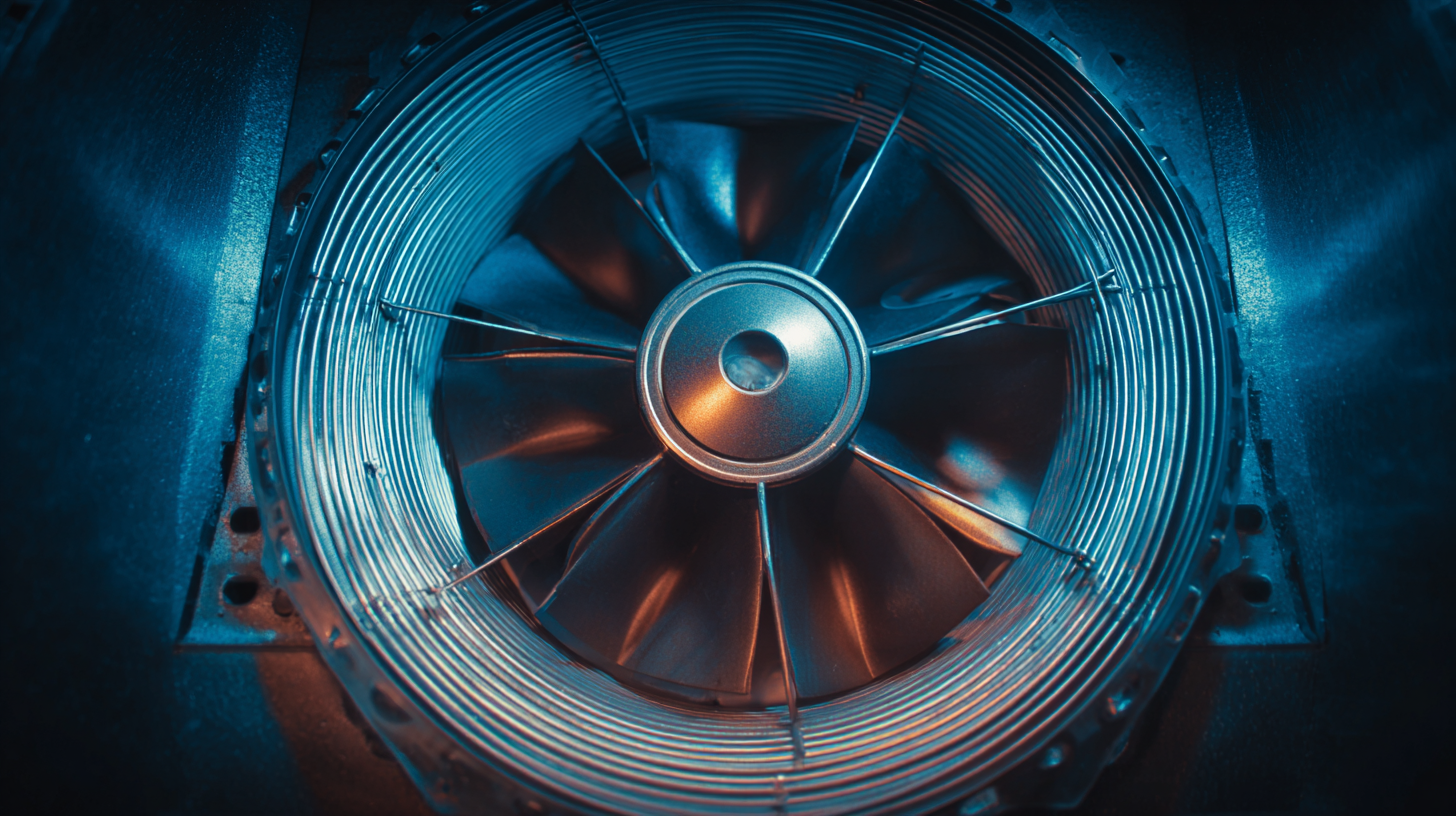

The design and structure of air chambers play a crucial role in enhancing performance and efficiency in various applications, from HVAC systems to pneumatic devices. An air chamber acts as a buffer, allowing for stable air pressure and smooth operation. Understanding the fundamental components, such as material choice, size, and shape, is essential for optimizing these chambers. For instance, selecting high-quality, durable materials can prevent leaks and ensure longevity, while carefully calculating the volume of the chamber can help it better accommodate fluctuations in air pressure.

Furthermore, the geometric configuration of an air chamber significantly influences airflow dynamics. A well-designed air chamber will minimize turbulence and facilitate smoother transitions, leading to improved energy efficiency. It is also advisable to pay attention to the inlet and outlet design, as these can affect both the performance and the responsiveness of the system. By fine-tuning these elements, engineers and designers can create air chambers that not only meet performance standards but also contribute to overall system efficiency, resulting in operational cost savings and enhanced reliability.

| Dimension | Value | Performance Impact | Optimization Tips |

|---|---|---|---|

| Volume | 150 liters | Higher Volume = Better Performance | Use larger chambers for more stability |

| Pressure Rating | 6 bar | Higher pressure = Increased output | Regularly check for leaks |

| Material | Aluminum Alloy | Lightweight & Durable | Choose high-quality materials |

| Insulation | 5 cm | Minimized energy loss | Ensure proper insulation thickness |

| Air Flow Rate | 250 m³/h | Optimal flow is key for performance | Optimize duct design for efficiency |

Implementing effective maintenance practices for your air chamber is crucial for ensuring its longevity and optimizing its performance. Regular inspection and servicing significantly reduce the risk of unexpected failures and extend equipment life. According to the International Air Quality Advisory Group, routine maintenance can improve system efficiency by up to 30% and reduce energy consumption, translating to significant cost savings over time. This proactive approach typically involves checking seals, filters, and pressure levels, which can prevent wear and tear and maintain optimal airflow.

Additionally, leveraging data analytics can revolutionize your maintenance strategy. The 2022 Industry Report on HVAC Efficiency shows that predictive maintenance powered by IoT sensors can lower operational costs by 25% while extending the lifespan of equipment by 20%. By analyzing real-time performance data, operators can identify potential issues before they escalate, allowing for timely interventions that ensure peak performance and mitigate costly repairs. Investing in these practices not only leads to improved efficiency but also aligns with sustainability goals by reducing waste and energy use.

Optimizing air chambers for maximum performance and efficiency can significantly enhance overall system functionality, particularly in advanced cooling technologies. Recent innovations depict the crucial role that sophisticated cooling systems play in various applications, from personal devices to industrial equipment. For instance, the integration of vapor chamber technology in electronics has showcased remarkable improvements in heat dissipation. Such systems utilize advanced cooling methods, including the manipulation of phase change in deionized water to efficiently manage thermal output, ultimately leading to enhanced device longevity and performance.

Moreover, developments in air flow technology, such as the introduction of specialized air management systems in metal 3D printing chambers, highlight the importance of maintaining optimal environmental conditions. By utilizing systems that effectively clear soot and debris, these innovations promote a clean build environment, which is essential for achieving high-quality prints. As air chambers become increasingly sophisticated, it is clear that leveraging advanced technologies not only promotes energy efficiency but also ensures improved performance across multiple sectors, paving the way for future advancements in cooling and environmental management.

When optimizing your air chamber for peak performance, it’s essential to identify and troubleshoot common issues that can disrupt efficiency.

One frequent problem is air leakage, which can significantly reduce pressure. To combat this, regularly inspect all seals and connections for any signs of wear or damage, and replace them as necessary. Ensuring that your air chamber is correctly sealed will help maintain constant pressure and enhance overall performance.

Another common issue is improper air balance within the chamber. An uneven distribution of air can lead to inefficiencies and performance inconsistencies. To address this, consider utilizing an air management system that monitors and adjusts air flow. Additionally, maintaining proper air pressure levels is crucial; too high or too low can impact your system’s effectiveness.

Tips: Always clean the air filter to promote optimal airflow and prevent blockages. Regular maintenance checks are vital—set a schedule to inspect your air chamber every few months. Finally, invest in quality equipment; using reliable components can mitigate many issues before they arise, saving you time and enhancing operational efficiency.